End-to-End Capabilities

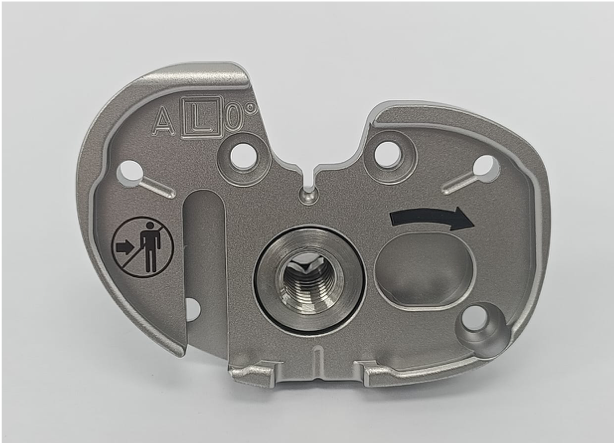

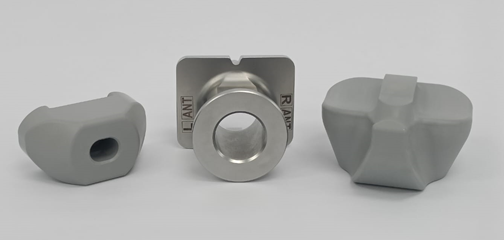

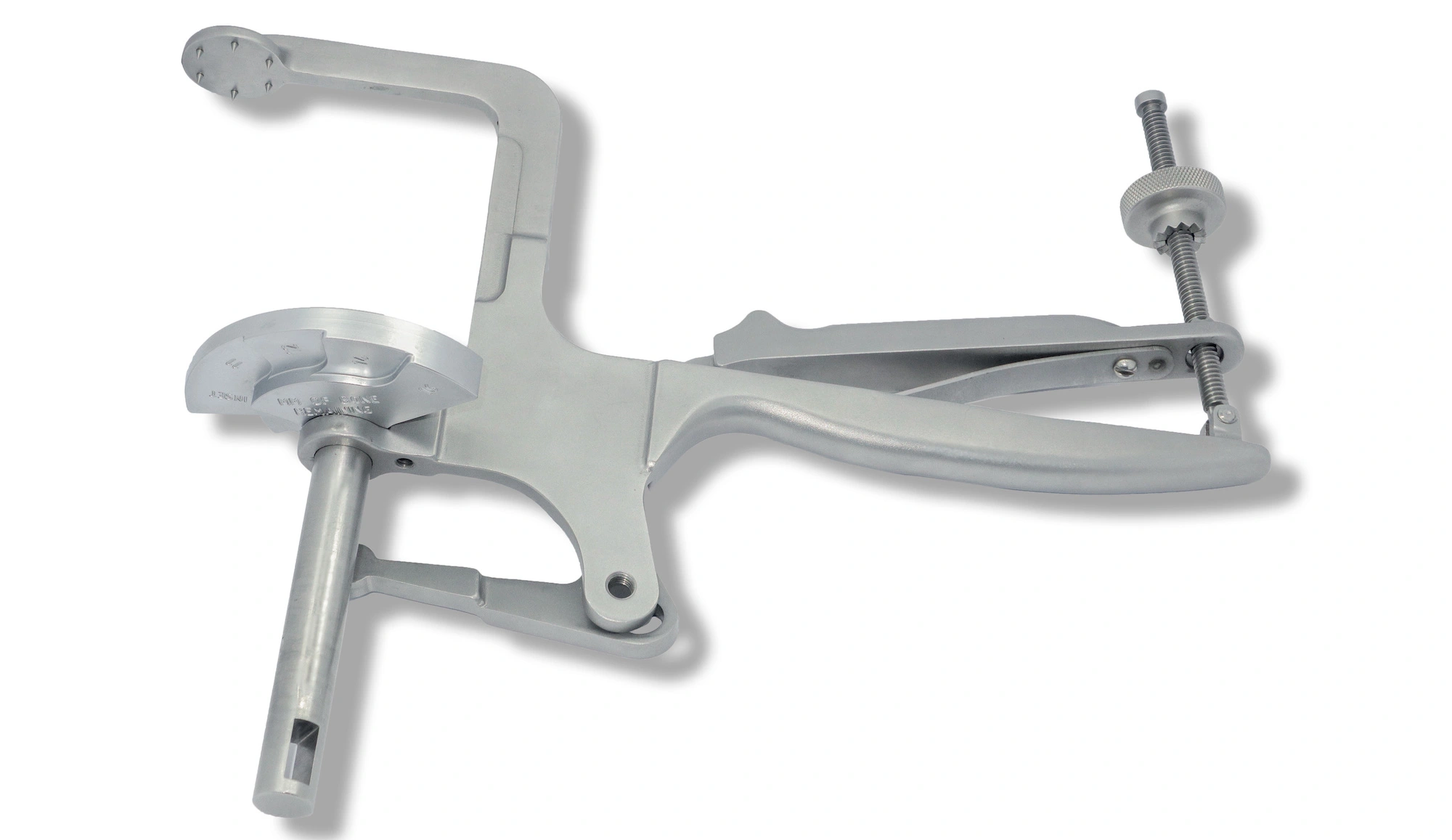

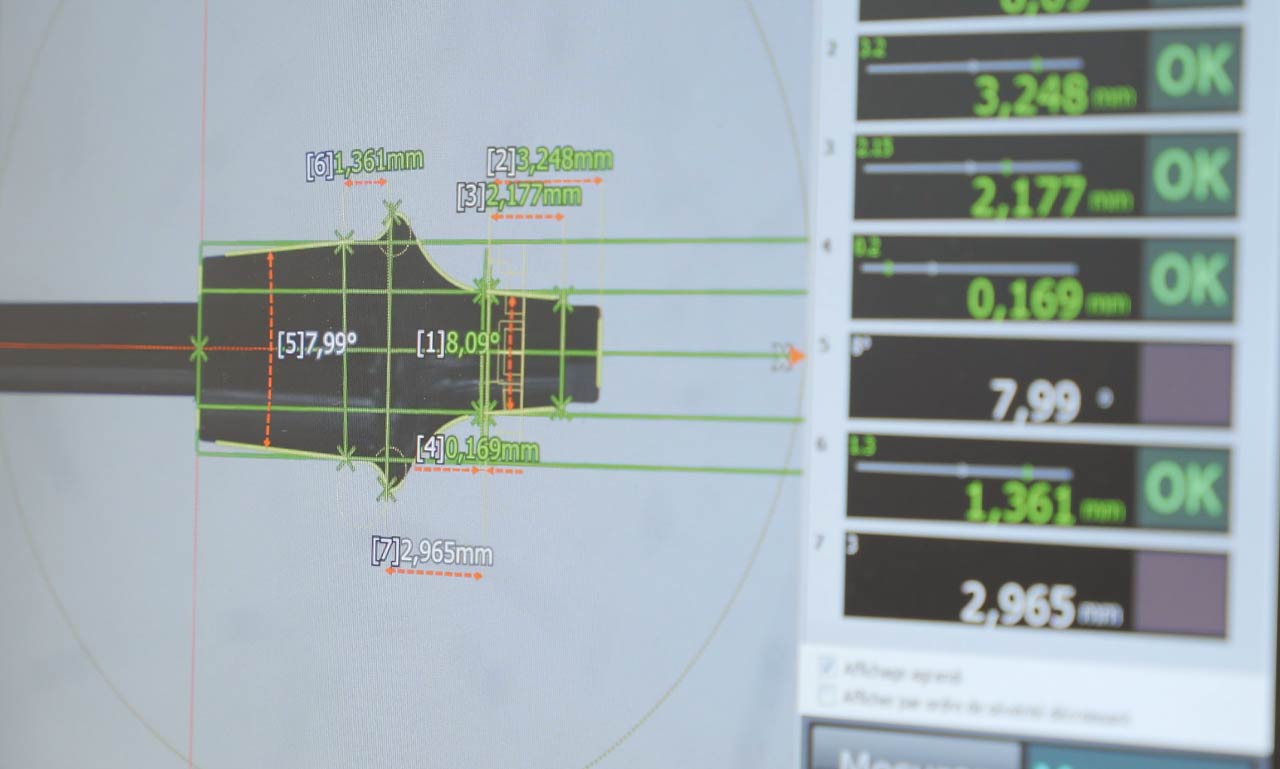

Team-Metal provides clients with a turnkey medical manufacturing service, including engineering, machining and assembly of custom medical components according to a high-mix low-volume manufacturing model.

- Custom design of medical components and instruments

- Biocompatible material sourcing and procurement

- Single point of contact

- Inventory hub for your medical components