High-Mix Low-Volume Manufacturing: Optimized Efficiency in Custom Machining

October 04, 2023

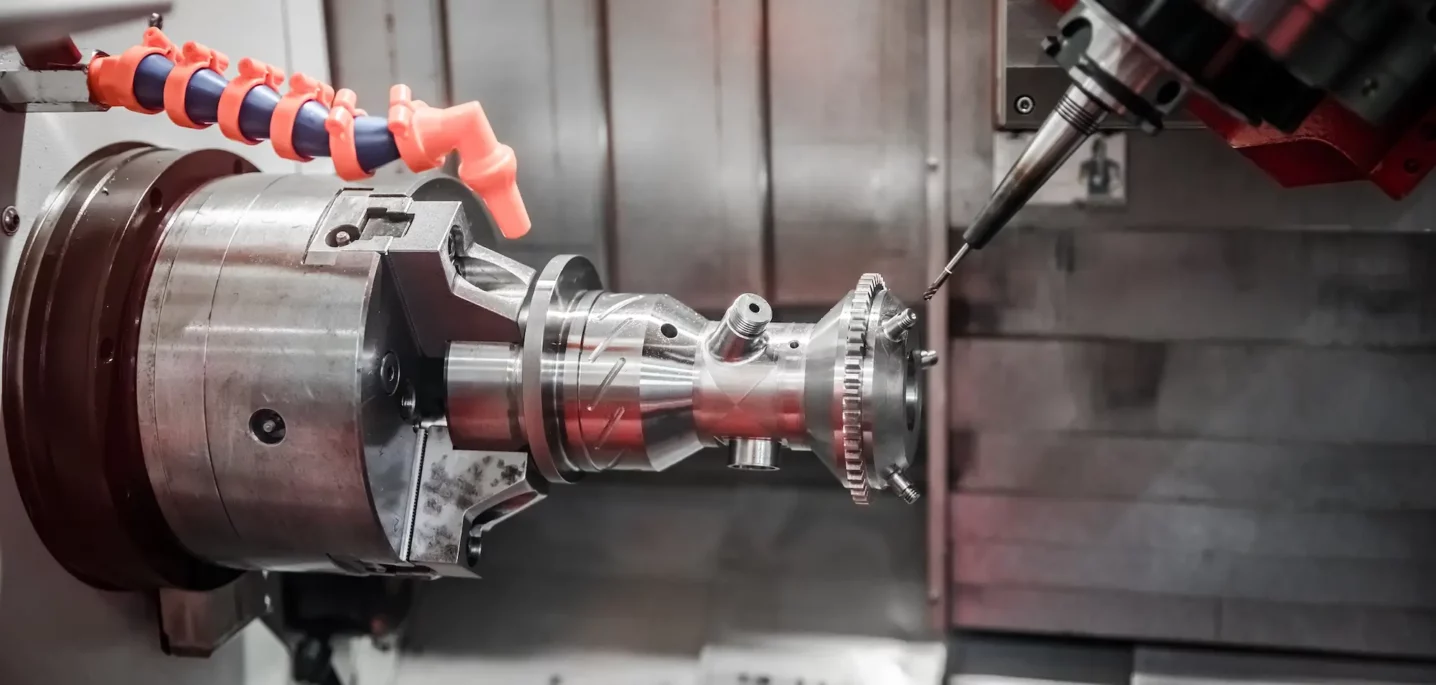

In the realm of manufacturing, High-Mix Low-Volume (HMLV) has emerged as a nimble and adaptable strategy, departing from the conventional mass production method. HMLV allows companies like Team-Metal to enhance operational flexibility and elevate customer service standards by enabling them to produce a diverse range of products in smaller quantities and respond swiftly to changing market dynamics and individual customer preferences.

In the ever-evolving landscape of manufacturing, businesses are constantly seeking innovative approaches to meet the demands of diverse markets while maintaining operational efficiency. One such strategy that has been taking the stage over from the traditional mass production method as a more flexible and responsive strategy is the “High-Mix Low-Volume” (HMLV) manufacturing. This approach stands in contrast to the previously popular one-size-fits-all approach that has gained significant popularity in past decades due to the increased introduction of automation tools in manufacturing processes. HMLV, however, offers a range of benefits that cater to the demands of today’s dynamic consumer preferences. It allows for a more personalised custom machining service, efficient and affordable value engineering, and rapid prototyping.

What is High-Mix Low-Volume Manufacturing

High-Mix Low-Volume manufacturing refers to a production strategy where a company produces a wide variety of products in relatively small quantities. HMLV enables manufacturers to embrace diversity and respond to changing market trends and individual customer demands with agility. This is especially beneficial for clients operating in fast-developing industries like medical technologies and life sciences. This dynamic production model is reshaping the landscape for manufacturers like Team-Metal and is proving to be a game-changer for both our operations and the level of customer service we can offer to our diverse clientele.

Customer-Centric Benefits of HMLV Manufacturing

Our decision to embrace HMLV manufacturing doesn’t just transform our operations; it profoundly benefits our valued customers too:

Tailored Solutions

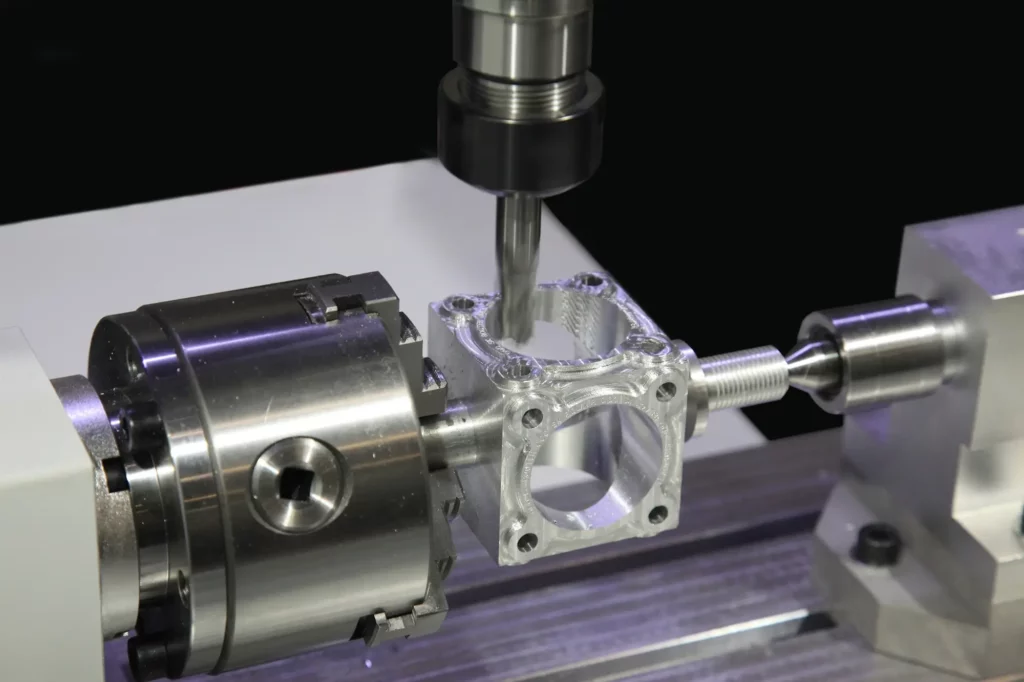

HMLV manufacturing enables us to craft precision machined parts that are precisely tailored to our customers’ specifications, resulting in parts that seamlessly integrate into their systems.

Shortened Lead Times

Time is of the essence for fast-developing modern industries. HMLV manufacturing drastically reduces lead times, ensuring that our customers receive the parts they need precisely when they need them. This agility supports their production schedules and enhances their efficiency.

Responsive Collaboration

With HMLV manufacturing, we can collaborate closely with our customers to accommodate design changes, troubleshoot challenges, and provide real-time solutions.

Cost-Effectiveness

While precision machining is known for its intricate processes, HMLV manufacturing optimises costs. Customers benefit from reduced tooling expenses, setup costs, and the ability to order precise quantities, eliminating waste.

Consistent Quality

Quality assurance is paramount in precision industries. HMLV manufacturing’s focus on quality control ensures that every part we deliver maintains the highest standards, promoting operational reliability for our customers.

Advantages of High-Mix Low-Volume Model for Manufacturers

As a manufacturer of precision machined parts catering to diverse industries, embracing the HMLV manufacturing model has unlocked a myriad of advantages for us:

Precision Customisation

In precision machining, every industry and each customer may have largely diverse needs with unique project specifications. HMLV manufacturing allows us to finely tailor each part to meet the specific requirements of our clients operating in a wide range of industries spanning from medtech, life sciences and analytics to lifestyle and office automation. This level of precision customization enhances client satisfaction and reinforces our reputation for excellence.

Agile Response to Industry Trends

Industries that rely on precision machined parts are known for their fast-paced evolution. HMLV manufacturing equips us to swiftly adapt to the latest industry trends when it comes to design or materials, ensuring that our offering is always aligned with the current needs of our clients.

Facilitated Innovation

HMLV manufacturing encourages innovation as we can experiment with new designs, materials, and production techniques without committing to massive quantities. This innovation-centric approach positions us as pioneers in the field, attracting clients seeking cutting-edge solutions.

Quality Enhancement

With smaller production runs, we can channel more attention and resources into stringent quality control measures and our own process improvements. Whether a client’s project requires a mix of machining and surface treatment techniques or a wholesome turnkey service, this manufacturing approach results in a remarkable reduction in defects and an overall improvement in the quality of our precision machined parts.

Sustainable Manufacturing

In a world increasingly focused on sustainability, HMLV manufacturing aligns perfectly. By producing only what’s required, we contribute to reducing waste and minimizing the carbon footprint associated with excessive production.

Optimised Inventory Management

HMLV enables us to produce parts as per immediate demand, mitigating the need for maintaining excessive stock in our inventory hub and reducing storage costs.

As a manufacturer of precision machined parts, our embrace of the High-Mix Low-Volume manufacturing model has ushered in a new era of responsiveness, innovation, and customer-centricity. Headquartered in Singapore, a booming manufacturing hub of Southeast Asia, and employing expert teams of component designers and engineers, we are optimally positioned to offer high-quality HMLV service to clients from different geographies. By aligning our operations with the diverse and rapidly changing needs of our clients, we’ve transformed our manufacturing process into a dynamic partnership that benefits both us and our valued customers. This revolutionary approach positions us at the forefront of precision machining, ready to meet the challenges and seize the opportunities of a rapidly evolving industrial landscape.

Latest News

ALL NEWS 21

21March

2024

Singapore’s Journey towards Industry 4.0

Read moreSingapore is poised to take the lead in promoting the development of Industry 4.0 for several reasons: advanced high-tech industries, ecosystem support, skilled workforce, focus on sustainability.

01

01February

2024

Team Metal Community Work – Beach Clean Up

Read moreWhat better way to spend a beautiful, breezy Saturday morning than coming together to clean our beach? On 6th Jan 2024, Team Metal Singapore organized our first event of the year – a beach clean-up day! We are happy that we can come together to make the environment cleaner for everyone, even though we are […]

20

20October

2023

Team-Metal Introduces Aluminum Electroless Nickel-phosphorus Plating for Enhanced Services and Quality Control

Read moreWe are excited to announce the expansion of our surface finishing services with the introduction of electroless nickel (EN) plating on aluminum.