Team-Metal Introduces Aluminum Electroless Nickel-phosphorus Plating for Enhanced Services and Quality Control

October 20, 2023

We are excited to announce the expansion of our surface finishing services with the introduction of electroless nickel (EN) plating on aluminum.

We are excited to announce the expansion of our surface finishing services with the introduction of electroless nickel (EN) plating on aluminum. While we have previously provided nickel plating for various substrates, such as stainless steel, the extension of this service to aluminum components now means that our clients can depend on us to deliver aluminum parts with improved corrosion resistance, enhanced hardness, a uniform coating and the capability to meet stringent tolerance requirements.

Furthermore, we have solidified our commitment to quality with investment in additional equipment designed for meticulous quality control specifically tailored for the electroless nickel plating process. This includes the acquisition of a Fischesrcope x-ray machine and a salt spray test machine, utilized for precise measurement of nickel coating thickness and its resistance to corrosion.

The Electroless Nickel Plating Process

Electroless nickel plating, or E-nickel plating, is a cutting-edge process that involves the even deposition of a nickel-phosphorus alloy onto solid substrates, such as metal or plastic. What sets this process apart is that it doesn’t require sophisticated anodes, external power, or an electrical current. Instead, it relies on a water solution containing nickel salt and a phosphorus-containing reducing agent, often a hypophosphite salt, to create a uniform and corrosion-resistant coating on the substrate.

The advantages of Electroless Nickel Plating on Aluminum

Electroless nickel plating on aluminum offers a unique set of advantages which place it high on the cost-to-quality scale compared to other metals. The lightweight nature of aluminum, combined with enhanced corrosion resistance and added hardness from electroless nickel plating, makes it a cost-effective alternative to heavier materials in various applications.

Enhanced corrosion resistance

Aluminum is known for its lightweight and corrosion-resistant properties, and with the addition of electroless nickel plating, its corrosion resistance is further bolstered, making it an ideal choice for applications in challenging environments, as is the case with components used in medtech, life sciences and analytics fields.

Increased Hardness

Nickel is known for its high Rockwell hardness values. Electroless nickel plating process significantly enhances the hardness of aluminum components without compromising their fatigue strength and ensuring long-lasting durability. Additionally, electroless nickel plating avoids issues like galvanization and cracking. These qualities are especially valuable in situations where components must withstand wear and stress, for example in lifestyle products and office automation systems.

Tight Tolerances

The uniformity of electroless nickel plating allows us to provide aluminum components that meet tight tolerance requirements along with their lightweight quality. This is especially valuable for our clients whose systems demand specialised precision components of very complex designs that conform to exact specifications.

Uniformity

Electroless nickel plating excels at coating surfaces uniformly. This immersion technique ensures that the plating process covers the entire surface area evenly, including complex geometries, corners, and edges. It is line-of-sight independent, making it versatile for components with intricate designs and even capable of passing through blind holes.

Equipment We Invested In

To further bolster our existing capabilities in nickel plating, we have invested in the following new equipment:

- FISCHERSCOPE® XUL® 220 X-RAY machine whose purpose is to measure the thickness of the nickel coating.

- T-machine salt spray test machine whose purpose is to check the corrosion resistance of the material surface and coatings. Test specification done as per ASTM B117 Standard.

Materials used as substrates for electroless nickel plating in this case are Alu 6061 & T651, and the process is done according to standard MIL- C26074. The thickness of the resulting coating layer is 0.010 – 0.015 Microns.

Meeting Diverse Client Needs

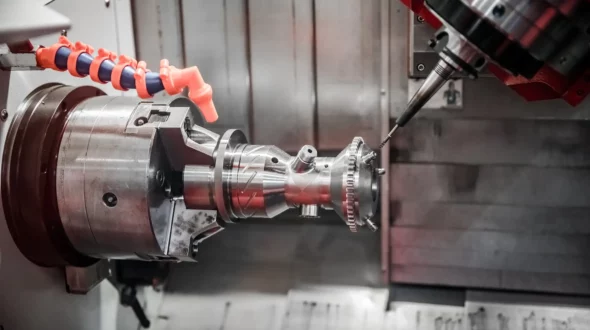

At Team-Metal, we understand that our clients have a wide range of requirements. The introduction of electroless nickel plating on aluminum, in addition to our existing CNC turning, milling, metal casting and surface finishing services, underscores our dedication to meeting all of our clients’ needs by enhancing versatility while maintaining the quality of our output. We believe that our commitment to offering comprehensive integrated solutions distinguishes us in the high-mix low-volume business model, and we are proud to continue exceeding our clients’ expectations.

With production facilities in Singapore, Indonesia and China, Team-Metal is a leading provider of a range of contractor precision machining services from product engineering and prototyping to turnkey manufacturing for a variety of OEMs in the medtech, life sciences, analytics, lifestyle and office automation fields. For more information about Team-Metal and our precision component manufacturing services, including electroless nickel plating, please don’t hesitate to contact our dedicated team for personalized assistance.

Latest News

ALL NEWS 21

21March

2024

Singapore’s Journey towards Industry 4.0

Read moreSingapore is poised to take the lead in promoting the development of Industry 4.0 for several reasons: advanced high-tech industries, ecosystem support, skilled workforce, focus on sustainability.

01

01February

2024

Team Metal Community Work – Beach Clean Up

Read moreWhat better way to spend a beautiful, breezy Saturday morning than coming together to clean our beach? On 6th Jan 2024, Team Metal Singapore organized our first event of the year – a beach clean-up day! We are happy that we can come together to make the environment cleaner for everyone, even though we are […]

04

04October

2023

High-Mix Low-Volume Manufacturing: Optimized Efficiency in Custom Machining

Read moreIn the realm of manufacturing, High-Mix Low-Volume (HMLV) has emerged as a nimble and adaptable strategy, departing from the conventional mass production method. HMLV allows companies like Team-Metal to enhance operational flexibility and elevate customer service standards by enabling them to produce a diverse range of products in smaller quantities and respond swiftly to changing market dynamics and individual customer preferences.