Singapore’s Journey towards Industry 4.0

March 21, 2024

Singapore is poised to take the lead in promoting the development of Industry 4.0 for several reasons: advanced high-tech industries, ecosystem support, skilled workforce, focus on sustainability.

In recent years, Singapore has emerged as one of the global leaders in embracing Industry 4.0, the fourth industrial revolution characterized by the integration of digital technologies into manufacturing and industrial processes. This shift represents a transformative journey towards smarter, more efficient, more sustainable, and interconnected production systems. Singapore’s commitment to this transition is evident through its robust infrastructure, government initiatives, and thriving ecosystem of innovation.

Understanding Industry 4.0

Industry 4.0 encompasses the convergence of digital technologies such as artificial intelligence, Internet of Things (IoT), robotics, additive manufacturing, and data analytics to revolutionize manufacturing processes across industries and all along the production and supply chain. It emphasizes the use of smart, connected systems to enhance efficiency, productivity, flexibility and sustainability in production.

Singapore’s Commitment to Industry 4.0: Public Initiatives

Singapore demonstrates clear commitment to embracing Industry 4.0, evidenced by various government initiatives and investments.

- The Advanced Manufacturing and Engineering (AME) Masterplan, launched by the government in 2016, outlines a clear roadmap for the development of advanced manufacturing capabilities, focusing on R&D, innovation, and supporting companies in adopting advanced manufacturing technologies.

- The Smart Industry Readiness Index (SIRI) provides companies with a framework to assess their readiness for Industry 4.0 adoption and develop roadmaps for digital transformation.

- Agency for Science, Technology, and Research (A*STAR) is a key player in Singapore’s Industry 4.0 efforts, as it supports research and innovation in areas like robotics, AI, and materials science.

- National University of Singapore (NUS) and Nanyang Technological University (NTU) are known for their research in AI, robotics, and other Industry 4.0 technologies. They work closely with industries on various projects.

Leading Industries in Singapore’s Shift to Industry 4.0

Best known as the industry at the forefront of Singapore’s shift to Industry 4.0 is the electronics sector, driven by semiconductor manufacturing. Precision manufacturing stands right next and closely related, as these both are leveraging advanced automation and IoT technologies to optimize production processes. The aerospace industry is embracing additive manufacturing and digital twin technologies to enhance aircraft design and maintenance. Furthermore, the biomedical sciences sector is utilizing AI and data analytics to accelerate drug discovery and improve healthcare outcomes.

The Significance of Precision Manufacturing

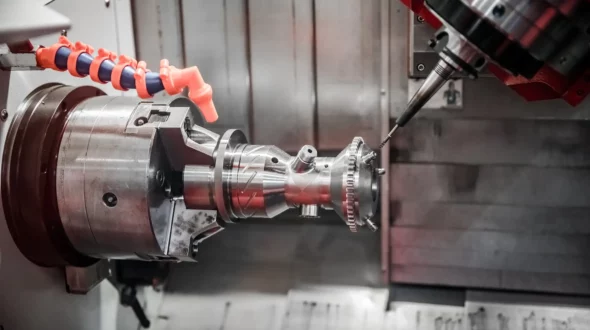

Precision manufacturing emphasizes the production of highly accurate and intricate components using advanced technologies such as CNC machining and 3D printing. In Singapore’s transition to Industry 4.0, precision manufacturing plays a crucial role as it ensures the seamless integration of digital technologies into production processes, resulting in greater efficiency and competitiveness. Moreover, it enables industries to achieve higher quality standards, reduce waste, and enhance product customization.

In this context, precision manufacturing experts operating within the high-mix low-volume model paradigm such as Team-Metal, play an important role. Contract manufacturing precision components for innovative OEMs across fields like medtech, life sciences and other high-tech industries, they support and facilitate the efficient development of new technologies in a sustainable manner.

Why Singapore is poised for Industry 4.0 Leadership

Several key factors contribute to Singapore being ideally positioned to lead an efficient and successful shift to Industry 4.0.

Local Assets

Its strategic location in Southeast Asia provides easy access to regional and global markets, facilitating trade and connectivity. Singapore’s own advanced infrastructure includes state-of-the-art logistics and transportation networks. This infrastructure enables seamless connectivity and supply chain integration and hence efficient movement of goods and information, essential for Industry 4.0 operations. Finally, Singapore boasts a highly educated and skilled workforce capable of leveraging advanced technologies for manufacturing excellence.

Collaboration and Ecosystem Support

Next to the Singaporean government’s strong commitment to innovation and technological progress, reflected in its policies and initiatives supporting Industry 4.0 transformation, the highly collaborative ecosystem in Singapore fosters partnerships between the government agencies, research institutions and industry players. This collaborative approach accelerates knowledge sharing and innovation generation, driving the adoption of Industry 4.0 technologies across various sectors.

Focus on Sustainability and Resilience

Singapore’s strong commitment to sustainability aligns with the principles of Industry 4.0. The advancement of green technologies and sustainable practices often relies on the adoption of digital innovations and automation, which not only reduce environmental impact but also enhance operational efficiency and cost-effectiveness of manufacturing processes.

It is evident that Singapore’s path toward Industry 4.0 reflects a strong commitment and strategic vision. Leveraging its unique positioning and local capabilities, firmly devoted to embracing digital technologies, Singapore confidently affirms its role as a global hub poised to shape the future of advanced manufacturing for years to come. As experts in precision manufacturing with operations spanning neighbouring countries and serving global clients, at Team-Metal we take pride in our involvement in this journey and our contribution to Singapore’s advancement toward achieving peak success in the transition to Industry 4.0.

References:

https://www.aseanbriefing.com/news/how-singapore-is-poised-to-take-advantage-of-industry-4-0/

a-star.edu.sg/docs/librariesprovider1/default-document-library/research/funding-opportunities/ame-programmatic-funds/ame-rie2020-programmatic-(updated-2018-06-09)_1.pdf

https://www.masterstudies.com/institutions/national-university-of-singapore/msc-in-industry-40

Latest News

ALL NEWS 01

01February

2024

Team Metal Community Work – Beach Clean Up

Read moreWhat better way to spend a beautiful, breezy Saturday morning than coming together to clean our beach? On 6th Jan 2024, Team Metal Singapore organized our first event of the year – a beach clean-up day! We are happy that we can come together to make the environment cleaner for everyone, even though we are […]

20

20October

2023

Team-Metal Introduces Aluminum Electroless Nickel-phosphorus Plating for Enhanced Services and Quality Control

Read moreWe are excited to announce the expansion of our surface finishing services with the introduction of electroless nickel (EN) plating on aluminum.

04

04October

2023

High-Mix Low-Volume Manufacturing: Optimized Efficiency in Custom Machining

Read moreIn the realm of manufacturing, High-Mix Low-Volume (HMLV) has emerged as a nimble and adaptable strategy, departing from the conventional mass production method. HMLV allows companies like Team-Metal to enhance operational flexibility and elevate customer service standards by enabling them to produce a diverse range of products in smaller quantities and respond swiftly to changing market dynamics and individual customer preferences.