Team-Metal Invests in Zirconia Blasting Machine

August 15, 2023

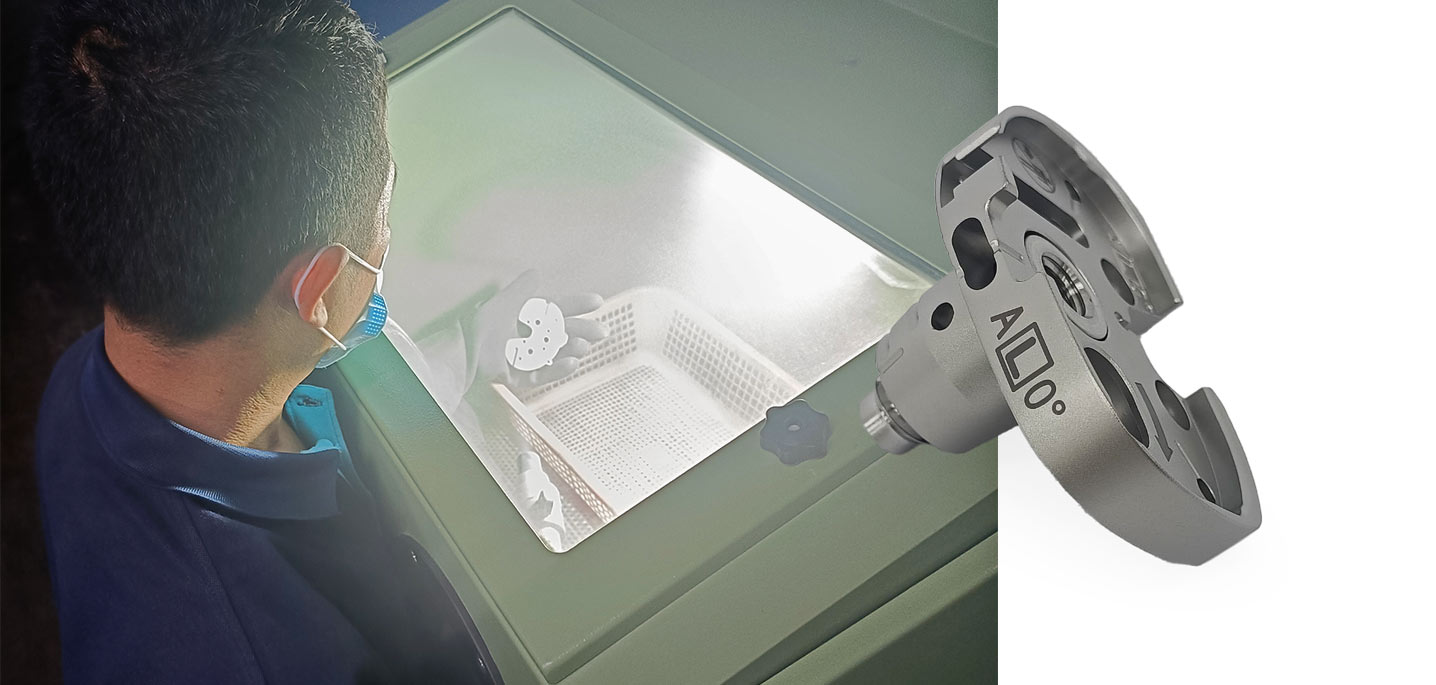

To reinforce its position as an all-in-one contract manufacturer, and to add to its surface finishing capabilities, Team-Metal has invested in a new Zirconia blasting machine. From April of 2023, Team-Metal clients have been able to order components with a Zirconia bead blast finish. This leaves parts with a clean homogenous surface free of oxides […]

To reinforce its position as an all-in-one contract manufacturer, and to add to its surface finishing capabilities, Team-Metal has invested in a new Zirconia blasting machine. From April of 2023, Team-Metal clients have been able to order components with a Zirconia bead blast finish. This leaves parts with a clean homogenous surface free of oxides and other impurities.

Why use Zirconia?

Zirconia Oxide is the ideal material for blasting because of its unique characteristics:

- Hardness and durability mean the beads maintain their integrity.

- The absence of iron produces minimal oxidation and contamination.

MedTech Components

Zirconia blast finishing is used regularly for MedTech parts and components as it removes impurities left over from the machining process while leaving the surface soft and blunt for increased safety. With this in-house capability, Team-Metal increases its capacity to produce MedTech components ready for use to its client across the globe.

What is Zirconia Bead Blasting?

Zirconia blasting is used to smoothen the surfaces of aluminium, bronze, brass, steel and other non-ferrous alloys to remove oxide, sand, rusts and burrs. It cleans various industrial parts, such as moulds and dies, engine components, turbine machinery parts, welded steel components, as well as forged and cast metals.

The process of Zirconia blasting comprises of the particle undergoing pressurized air to create high velocity to impact onto the treated surface. This removes dirt and burrs around sharp edges that creates a smooth and safe surface. Due to the flexibility of bead forms size, user can provide a controlled and precise surface preparation. Depending on the size and shape of the Zirconia particles, along with the blasting pressure and angle, this process can be adjusted to achieve different surface profiles and finishes.

If you want to learn more about our Zirconia blasting process or any other of the surface treatment processes Team-Metal offers, feel free to send us an inquiry.

Latest News

ALL NEWS 21

21March

2024

Singapore’s Journey towards Industry 4.0

Read moreSingapore is poised to take the lead in promoting the development of Industry 4.0 for several reasons: advanced high-tech industries, ecosystem support, skilled workforce, focus on sustainability.

01

01February

2024

Team Metal Community Work – Beach Clean Up

Read moreWhat better way to spend a beautiful, breezy Saturday morning than coming together to clean our beach? On 6th Jan 2024, Team Metal Singapore organized our first event of the year – a beach clean-up day! We are happy that we can come together to make the environment cleaner for everyone, even though we are […]

20

20October

2023

Team-Metal Introduces Aluminum Electroless Nickel-phosphorus Plating for Enhanced Services and Quality Control

Read moreWe are excited to announce the expansion of our surface finishing services with the introduction of electroless nickel (EN) plating on aluminum.